RESEARCH AND EDUCATION

RESEARCH LINES

EDUCATION

POWER SYSTEMS INTEGRATION AND RELIABILITY

Power Systems Integration and Reliability research sub-line aims at the development of new technologies and methods allowing the implementation of semiconductor power devices in power electronics systems with higher levels of integration and reliability. This line covers different topics between power device and application converters, with main focus on four different areas: Thermal Management, Power Packaging Technologies, Electro-thermal Characterization and Reliability.

Bridging the gap between the power device and its application.

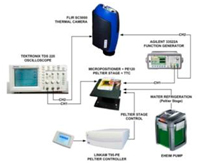

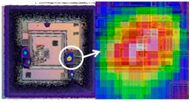

Thermal management

Design of new packages and modules for high efficiency cooling, based on 3D thermal simulation (FLOTHERM and COMSOL).Thermal parameters identification (conductivity).Thermal characterization of the developed systems with thermography equipment (mainly IR cameras) and thermal impedance measurement set-ups. Thermal evaluation of materials and components: close relationship with science materials and end-user partners.

Thermal simulation result (temperature map) of a compact DC/DC converter.

Electro-Thermal characterization of LED lamps (CSSL Eniac Project)

Detailed thermal characterization of Philips LED lamps by means of IR thermography anddirect temperature measurements for simulation purposes allowing the development of a new generation of SSL bulbs.

From left to right: Thermocouples location in a Philips MasterLED lamp. Transient thermal response of the LED lamp. Surface temperature map of the LED lamb (IR thermography).

Power packaging technologies

Development and fabrication of new packages and modules for high- power, high-temperature and high levels of integration power systems. Specific and generic fabrication equipment available in clean-room environment: reflow ovens, wire-bonding, shear/pull tests, SAM inspection, etc. New interconnection technologies. Added value power module prototyping: specific functions, new cooling technologies, use of new materials, etc.

Interconnection technology based on power bumps (2001 patent with ALSTOM).

Development of specific power modules

Development and study of new power modules for electrical vehicle integrating thermoelectric cells for improving their heat dissipation and allowing advanced thermal management solutions (temperature regulation). Patent with LEAR Corporation (USA) in the framework of CENIT-VERDE project.

From left to right: Thermo-electrically cooled power module: 600 V – 40A half-bridge topology. Thermal response of the thermo-electrically cooled power module.

Electro-thermal characterization

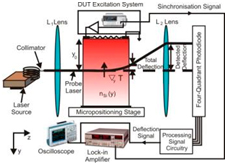

Development of advanced measurement set-ups for electro-thermal characterization at chip and system level based on: i) Optical methods for depth-resolved characterization at chip level: Free-Carrier Absorption, Internal IR Laser Deflection (IIR-LD), Fabry-Perot Interference. ii) Surface-resolved electro-thermal characterization: IR thermography, Liquid crystal thermography, CCD-thermo-reflectance thermography. Study of modulated heat sources by lock-in detection for non-invasive evaluation of structural defaults, extraction of Figures of Merit in Frequency (FOMs) from IC/device internal nodes, and local physical parameters in devices.

IR thermal map of an LED lamp driver.

Lock-in thermal sensing for device & IC debugging

Detection of heat sources modulated in frequency using IR cameras and IIR-LD techniques. Non-invasive determination of hot spots for IC’s and power devices debugging. Main contribution: use of heterodyne detection techniques.

From left to right: Depth-resolved inspection (IIR-LD / FPI techniques). Surface inspection (IR camera). Hot-spot detection in a wire-less pad-free sensing IC.

Reliability

New methodologies for the analysis of the reliability/ruggedness limits (lifetime) of advanced power devices and systems. Understanding the physics of electro-thermal instabilities, to link them to the physics of the device destruction during tests at limit (outside SOA), effects of aging (SOA degradation), and effects of radiation (radiation hardness studies). Special focus on wide bandgap devices oriented to high temperature applications and monolithically integrated power devices in Silicon (e.g., transistor and diode monolithically integrated). Investigate structures/solutions to improve device robustness at chip level (design for ruggedness).

SiC Schottky diode damaged during surge-current tests.

Studies on ruggedness & failure mechanisms

Studies on ruggedness & failure mechanisms in power devices (Si, SiC).Failure location in SiC diodes after surge current tests.

From left to right: Surge current test set-up. Failure location in SiC diodes by lock-in IR thermography. Failure mechanism analysis (FIB – SEM).